Just when we thought 3D printing had reached its limits — with faster printers, multicolor setups, and endless filament options — the tech world throws three game-changing moves that completely redefine what “additive manufacturing” can mean.

From electronics that print at room temperature, to metal and ceramic systems finally within reach of small studios, and even earth-based housing, 2025 might just be the year 3D printing steps beyond the maker bench and into every industry.

Let’s break down what’s shaking the foundations of modern fabrication.

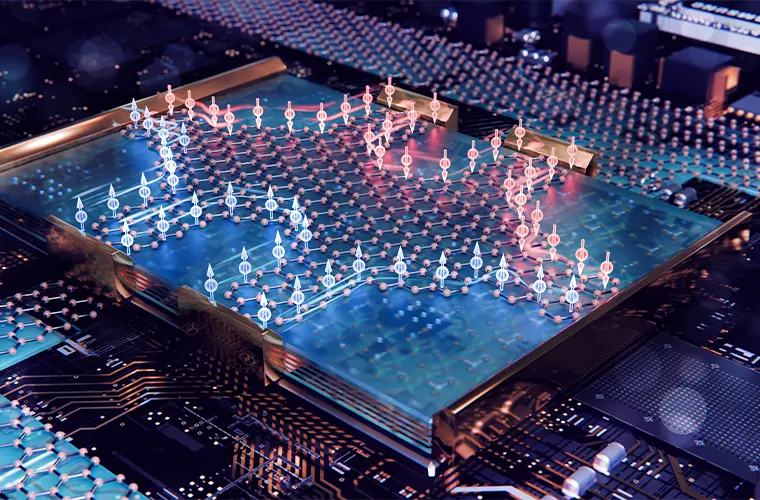

1. KAIST Prints the Impossible — Electronics at Room Temperature

The Korea Advanced Institute of Science and Technology (KAIST) has unveiled a process that could rewrite the rulebook for how we create sensors and semiconductors.

Their new room-temperature 3D printing technique can fabricate functional infrared sensors using liquid nanocrystal inks — layering metals, semiconductors, and insulators without heat.

That means no furnaces, no cleanroom, and no 600 °C sintering step.

Just straight-up printing, like you’d print a toy or part — but it’s a functioning piece of hardware.

This innovation bridges the gap between additive manufacturing and microelectronics. Think about:

- Flexible LiDAR units that curve around vehicles or helmets.

- Smart wearables with built-in thermal vision.

- Medical devices that “see” through heat patterns.

It’s the marriage of material science and maker creativity, and it opens the door for true electronic-mechanical hybrid prints — something that even the most advanced pros have struggled to achieve.

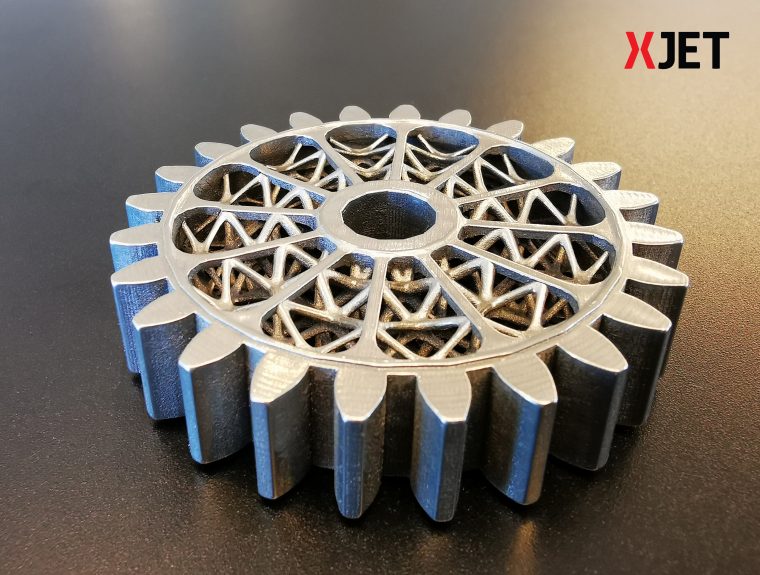

🛠️ 2. XJet’s Carmel Pro Brings Metal & Ceramic 3D Printing to the Masses

Meanwhile, XJet just dropped a bombshell at the pre-Formnext 2025 preview: the Carmel Pro.

This new machine takes the high-end world of metal and ceramic 3D printing — once a fortress of million-dollar systems — and makes it accessible to small labs, research centers, and innovative makers.

What’s the big deal?

XJet’s technology uses NanoParticle Jetting, producing parts with insane surface finish and strength rivaling machined metal.

But with the Carmel Pro, they’ve miniaturized the system, reduced maintenance, and cut operational costs.

That means the future could look like this:

- Print a titanium gear prototype in your workshop.

- Add ceramic components to custom mechanical builds.

- Integrate heat-resistant or conductive materials into hybrid 3D prints.

It’s industrial power — scaled down for creators.

And with Formnext 2025 around the corner, expect to see even more compact, smarter AM systems entering the “prosumer” tier.

3. Printing Homes from Earth — Sustainability Meets Scale

While labs are getting smaller, printers are getting bigger — and dirtier, in the best way possible.

In Australia, Swinburne University of Technology researchers are developing earth-based 3D printing systems that use plant fibers and robotics to build full-scale houses.

Their mission: fix the growing housing shortage with eco-friendly, fast-to-build homes using local soil and bio-materials.

This method reportedly cuts costs by 60% and construction time nearly in half.

The brilliance lies in combining ancient earth-building traditions with robotic precision — a perfect example of old meets new.

It’s the kind of sustainability story that proves additive manufacturing isn’t just about gadgets; it’s a tool for solving global crises.

Imagine entire neighborhoods printed with zero waste — customizable, beautiful, and carbon-neutral.

Why This Matters for Makers and Innovators

These three breakthroughs share a single pulse: accessibility.

- KAIST’s tech brings electronics within reach of desktop labs.

- XJet’s Carmel Pro brings metal & ceramics down to small-studio scale.

- Swinburne’s work brings architecture to the frontier of sustainability.

Whether you’re printing collectibles, mechanical parts, or full-blown devices, the gap between “maker” and “manufacturer” is closing fast.

The next evolution of 3D printing isn’t just about better nozzles or faster slicers — it’s about new materials, cross-disciplinary design, and freedom to experiment.

The Takeaway

2025 is shaping up to be the year where 3D printing goes beyond plastic and steps into everything else: metal, ceramics, electronics, and even dirt.

For creators, innovators, and entrepreneurs alike, the message is clear:

Keep your printer ready, your imagination wild, and your eyes on the horizon — because the next revolution might start right on your build plate.